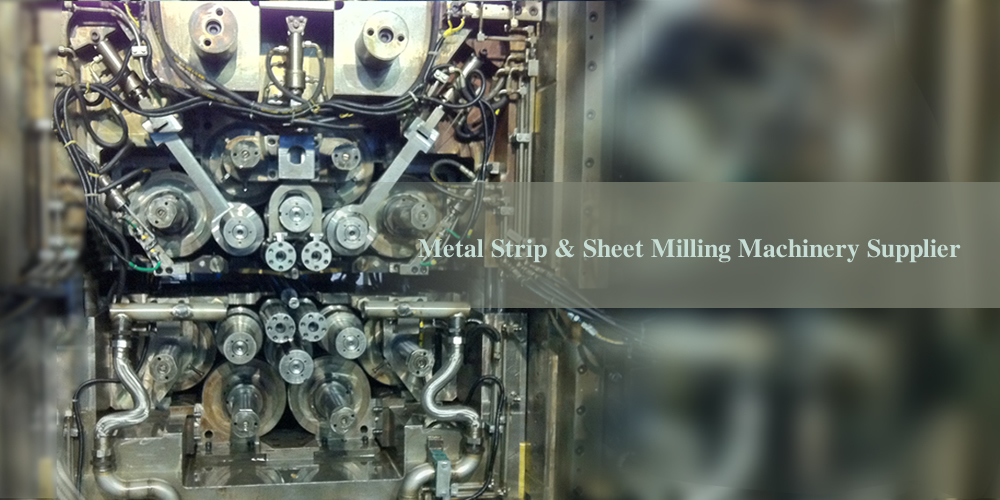

6-Hi Reversing Rolling Mill

1. Advantages of 6-hi reversible rolling mill

HC type 6Hi reversible single stand cold rolling mill, rolling mill is provided with has a bending and shifting,With uncoiler, entrance&exit coiling machine, thickness tester, laser velocimeter, can realize large tension rolling, ensure a relatively thin Metal strip high speed and stable production.

2. Coiling parameters

2.1 Raw materials

Raw Materials | |

Texture of material | Metal and Alloys |

Material Thickness | Max3.5mm |

Material Width | Max1250mm |

Inside Diameter | 610mm |

Outer Diameter | 900-2100mm |

Material Weight | Max25Ton |

2.2 Finished product

Finished Product Parameters | |

Finished thickness | 0.50-0.15mm |

Coil Width | Max1250mm |

Inside Diameter | Φ610mm |

Outer Diameter | Φ900-2200mm |

Coil Weight | Max25Ton |

3. Main Technical Parameters of the Rolling Mill

Mill specification | Six rolling mill reversible |

Maximum Rolling Pressure | Non - Standard (width, thickness, material properties) |

Rolling Speed | Max1200m/min |

Coiling Tension | Max30Ton |

Mill Speed Precision | 1% |

Tension Precision(FS) | The dynamic fluctuations in the value of less than 4%. Steady state: fluctuations in the value of less than 1.5% |

Bending Force | Non - Standard (width, thickness, material properties) |

Hydraulic Drive System | 12Mpa |

Bending System Pressure | 16Mpa |

AGC System Pressure | 21Mpa |

4.1 Mechanical equipment

No. | Device name | Unit | Quantity | Note |

1 | Uncoiler | Set | 1 | Custom |

2 | Pinch straightener | Set | 1 | Custom |

3 | Entrance coiler | Set | 1 | Custom |

4 | Entrance side platform | Set | 1 | Custom |

5 | Rolling mill housing | Set | 1 | Custom |

6 | Rolling mill drive | Set | 1 | Custom |

7 | Exit side platform | Set | 1 | Custom |

8 | Exit coiler | Set | 1 | Custom |

9 | Rolls | Set | 1 | Custom |

10 | Middle Roll Shifting | Set | 2 | Custom |

11 | Bending and balancing device | Set | 4 | Custom |

12 | Oil removal unit | Set | 2 | Custom |

13 | Tension testing | Set | 2 | Custom |

14 | Turning Roll | Set | 2 | Custom |

15 | Roll changing Device | Set | 1 | Custom |

4.2 Motor, electronic control and instrument system

No. | Device | Unit | Quantity | Specification |

1 | Uncoil Motor | Set | 1 | AC OR DC |

Mill Motor | Set | N | AC OR DC | |

3 | Coil Motor | Set | N | AC OR DC |

4 | (Siemens PLC) | Set | 1 | SIEMENS |

5 | (AGC) | Set | 1 | SIEMENS PLC |

6 | (Gauge) | Set | 1 | AMC |

No. | Device | Unit | Quantity | Specification |

Low pressure hydraulic station | Set | 1 | Custom | |

2 | AGC hydraulic station | Set | 1 | Custom |

Screw-down cylinder | Set | 2 | Custom | |

3 | Process lubrication system | Set | 1 | Custom |

4 | Gear oil lubrication | Set | 1 | Custom |

5 | Oil mist collection & purification | Set | 1 | Custom |

6 | Automatic fire extinguishing device | Set | 1 | Custom |

5. Characteristics of rolling mill

5.1 HC cold rolling mill;

5.2 Positive and negative bending roll;

5.3 Middle Roll Shifting;

5.4 Hydraulic Screw-down;

5.5 Passline Auto Adjusting;

5.6 Constant Tension Control;

5.7 Sectional cooling;

5.8 Auto Change Roll;

5.9 AGC uses high-speed controller SIEMENS FM458 and hydraulic servo system to achieve high accuracy and fast response. With the laser velocimeter, accurate second mass flow AGC control is achieved.

中文版

中文版 English

English WeChat

WeChat

Alibaba Shop

Alibaba Shop